To achieve the level of accuracy required in aggregate weighing, the choice of load cell is paramount. While there are various load cell types available, shear beam load cells are the industry standard for aggregate batching scales—and for good reason. Their design, functionality, and durability are perfectly suited to the harsh conditions and precise demands of concrete batching plants.

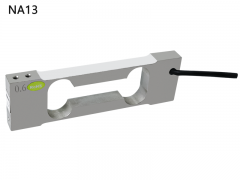

Let’s break down how shear beam load cells work. At their core, these load cells are elastic metal structures with one end rigidly fixed and the other end free to receive the load from the aggregate hopper. Precision strain gauges are bonded to the elastic body—usually on the top and bottom surfaces near the fixed end, where bending deformation is most pronounced. When aggregate fills the hopper, the weight exerts a downward force on the free end of the cantilever, causing it to bend slightly: the top surface stretches and the bottom surface compresses.

These tiny deformations change the electrical resistance of the strain gauges, which are wired into a Wheatstone bridge circuit. The bridge converts the resistance change into a small voltage signal, which is then transmitted to a weight indicator or the plant’s central control system. The system amplifies and processes this signal to display the exact weight of the aggregate—and triggers the silo gate to close once the target weight is reached.

Welcome to visit Mavin website www.mavin.cn to get more info and the best prices for high precision load cells.

English

English français

français русский

русский italiano

italiano español

español português

português العربية

العربية Türkçe

Türkçe